Construction is a mammoth industry, growing at a steady pace of around 6% globally, and is expected to reach USD 19.52 trillion in 2027, according to the Business Research Company. Mordor Intelligence, a market intelligence and advisory firm, puts the current size of India's construction market at around USD 639 billion. As a large employer, the industry accounts for around 9% of India’s GDP, and the country is projected to become the world’s third-largest construction market after China and the US. Artificial Intelligence (AI) and Digital Twins are fast revolutionising the construction industry by helping it overcome its toughest challenges such as safety concerns, labour shortages, and cost and schedule overruns. We reached out to Col (Dr) Gaurav Singh, Chief Technology Advisor at Pinkerton, a leading global provider of security and risk management solutions, to assess the impact of the Artificial Intelligence and Digital Twins on the construction industry and what it means for the sector. Dr Singh, a former Indian Army officer, earned his PhD and M.Tech from IIT Delhi. He is a multifaceted technocrat and industry leader who has driven AI applications to impact topline in several businesses, such as airports, ports, energy and real estate with forward and backward integration of various applications. Here are excerpts from a long interview:

1. What exactly is a Digital Twin and how does the technology help in the construction industry?

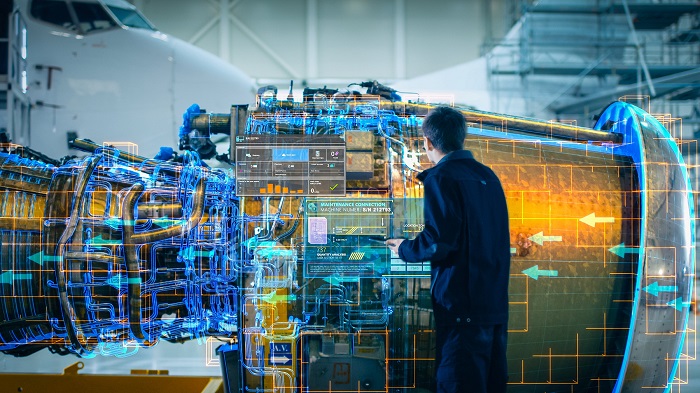

A Digital Twin is a dynamic, real-time digital replica of a physical asset, system, or process. It reflects the actual state and behaviour of the physical counterpart. They incorporate real-time data from sensors and IoT devices, allowing for continuous updates and interactions with the physical entity. Digital Twins are used for monitoring, simulating, and analyzing performance throughout the lifecycle of the asset, including operation and maintenance. They incorporate real-time data from sensors and IoT devices, allowing for continuous updates and interactions with the physical entity.

In the construction industry, Digital Twins are used for ongoing monitoring and optimization throughout the lifecycle of an asset, providing a real-time connection to the physical world.

Digital Twins leverage real-time data, in Projects and O&M Phase, for ongoing management and optimization. It leads to better collaboration, informed decision-making, risk reduction, lifecycle optimization, sustainability, and preparedness, resulting in more successful construction projects.

2. How fast are Artificial Intelligence (AI) and Digital Twins being adopted in the construction sector globally? Is India on a par with the pioneering nations on this front?

The adoption of Artificial Intelligence (AI) and Digital Twins in the construction sector is progressing rapidly on a global scale, driven by the need for improved efficiency, safety, and sustainability.

Global adoption trends show a strong increase in investment by leading construction firms and technology companies in AI and Digital Twin technologies. These investments are particularly focused on enhancing project management, design, safety, and facility management. The construction sector is also embracing these technologies as part of the broader Industry 4.0 movement, which emphasizes automation, data exchange, and smart technology integration. The use cases for AI and Digital Twins are expanding, with applications in predictive maintenance, energy management, and real-time monitoring of construction sites. This trend is especially prominent in regions such as North America, Europe, the Middle East, and Asia. Furthermore, there is a significant push towards standardization and regulatory frameworks, which is facilitating the accelerated adoption of these technologies across the industry.

India’s position in the Digital Twin market is marked by a robust CAGR of 40%. The country is witnessing a steady yet impactful adoption of AI and Digital Twin technologies within the construction sector, with companies increasingly acknowledging their potential to improve project efficiency and safety. Government initiatives, such as the Digital India program and various smart city projects, are also fostering the use of advanced technologies in construction and urban development, setting the stage for further growth. However, challenges persist, including a skills gap, resistance to change, and infrastructure limitations, which continue to slow the rapid adoption of AI and Digital Twins. Many Indian firms remain in the early stages of implementation compared to leading nations. Despite these challenges, the rise of construction-focused startups offering innovative solutions using AI and Digital Twins is accelerating industry adoption. Additionally, Indian construction companies are increasingly collaborating with global firms to gain access to advanced expertise and technologies, bolstering their capabilities in this transformative field.

While AI and Digital Twins are being adopted rapidly on a global scale, India is making significant strides but still has some way to go to catch up with pioneering nations. The combination of government support, growing awareness, and the emergence of tech-driven startups is likely to accelerate this process, positioning India as a key player in the adoption of these advanced technologies in the construction sector.

4. What notable improvements have been seen in projects that have implemented Digital Twins?

Overall, projects that have integrated Digital Twins alongside the traditional Building Information Modeling (BIM) have experienced enhanced operational efficiencies, better predictive capabilities, improved collaboration, and more sustainable practices. These advancements contribute to more successful project outcomes and greater long-term value.

5. Can you provide examples of projects that have successfully implemented Digital Twins?

There are several examples of projects that successfully implemented Digital Twins.

Siemens developed a Digital Twin (The Siemens City Performance Tool) for urban planning in cities, allowing stakeholders to simulate various urban scenarios. Notable improvements included enhanced decision-making and sustainability. Second is the DigiTwin for the City of Helsinki. The Digital Twin was used here to model and analyse city infrastructure and services. Improved visualization tools have enhanced public engagement in urban planning processes, leading to better-informed community decisions. Another example is Kuwait International Airport that utilised a Digital Twin for its expansion project to streamline operations and enhance passenger experience. Under the Singapore Smart Nation Initiative, Singapore is developing a national Digital Twin to simulate the entire city-state for planning and management.

Aldar Properties' Digital Twin for its headquarters enabled real-time energy monitoring and adjustments, leading to a 20% reduction in energy consumption.

These examples illustrate how implementing Digital Twins has led to significant improvements in decision-making, operational efficiency, sustainability, and occupant experience. The ability to integrate real-time data and simulate various scenarios sets Digital Twins apart from traditional BIM approaches, leading to more successful project outcomes and enhanced long-term value.

What role will Digital Twins play in construction project management and maintenance in the future?

Digital Twins will revolutionize construction project management and maintenance by providing real-time insights, enhancing collaboration, optimizing operations, and supporting predictive maintenance. Their ability to integrate various data sources and facilitate data-driven decision-making will lead to more efficient, resilient, and sustainable construction practices, ultimately transforming the built environment.

Are the AI and Digital Twins being applied to big structures alone or are they useful and financially viable for smaller constructions as well?

AI and Digital Twins are valuable tools for both large and small construction projects. They provide significant benefits in terms of efficiency, cost savings, maintenance, and decision-making, making them a financially viable option across a range of construction types. As technology becomes more accessible, the adoption of Digital Twins in smaller constructions is likely to grow, leading to improved project outcomes and enhanced asset management.

What are the main challenges in implementing AI and Digital Twins in the construction sector?

While implementing AI and Digital Twins in the construction sector presents challenges, many organizations are finding ways to overcome these obstacles. Successful implementation often involves careful planning, investment in training, and a commitment to fostering a culture of innovation. By addressing these challenges, firms can unlock the significant benefits that AI and Digital Twins offer, leading to improved efficiency, better decision-making, and enhanced project outcomes.

How do these technologies make construction budgeting more accurate and smart?

By leveraging real-time data, predictive analytics, and integrated information from various sources, AI and Digital Twins significantly enhance the accuracy and intelligence of construction budgeting. These technologies enable project teams to make more informed decisions, adapt to changing conditions, and ultimately improve project financial performance.

Can these advanced technologies reduce construction project costs?

By enhancing accuracy in estimation, enabling real-time monitoring, optimizing resource use, and improving overall project management, AI and Digital Twins can lead to substantial cost savings in construction projects. These technologies provide the tools necessary to manage expenses more effectively, mitigate risks, and ultimately deliver projects within budget.

What role can AI play in green building and sustainability in the construction sector?

AI can play a pivotal role in promoting green building and sustainability in the construction sector through various applications and technologies. AI algorithms can analyse building designs and recommend changes to optimize energy efficiency. AI can evaluate the environmental impact of various materials, helping architects and builders choose sustainable options with lower carbon footprints. Artificial Intelligence can track material usage on-site and analyse data to minimize waste generation. Predictive analytics can forecast material needs more accurately, reducing over-ordering. It can assist in identifying recyclable materials in construction waste, facilitating better recycling processes and promoting the reuse of materials in new projects. AI can explore multiple design alternatives based on sustainability criteria, allowing architects to create buildings that maximise efficiency and minimise resource use. The AI can analyse site conditions and environmental impacts, guiding designers to make informed decisions that enhance sustainability and reduce ecological footprints.

Moreover, AI can assist in monitoring compliance with sustainability regulations and standards, ensuring that projects meet required environmental criteria. AI can streamline the data collection and reporting processes needed for sustainability certifications, making it easier for firms to achieve and maintain green building certifications.

How can AI help in improving the safety of construction workers?

AI can play a transformative role in enhancing the safety of construction workers by providing real-time monitoring, predictive analytics, effective training, and improved communication. By leveraging these technologies, construction companies can create safer work environments, reduce the risk of accidents, and promote a culture of safety that protects workers and enhances overall project efficiency.

Which areas of construction have the maximum scope to benefit from AI or Digital Twins?

While AI and Digital Twins can enhance various aspects of construction, areas like project management, design and architecture, and building operations and maintenance have the most significant scope for benefit. These areas can leverage real-time data, predictive analytics, and collaborative technologies to drive efficiency, safety, and sustainability, ultimately transforming the construction process.